When it comes to drilling, milling, and sawing operations that are tailored to the surface, floating units are the right choice. They deliver precise and consistent results thanks to automatic, mechanical compensation for plate tolerances and clamping inaccuracies. For high-speed machining (e.g. engraving), floating units must be optimized for these applications to avoid the risk of production downtime. As Georg Ackermann GmbH now knows, large and powerful does not necessarily mean stable in aggregate technology.

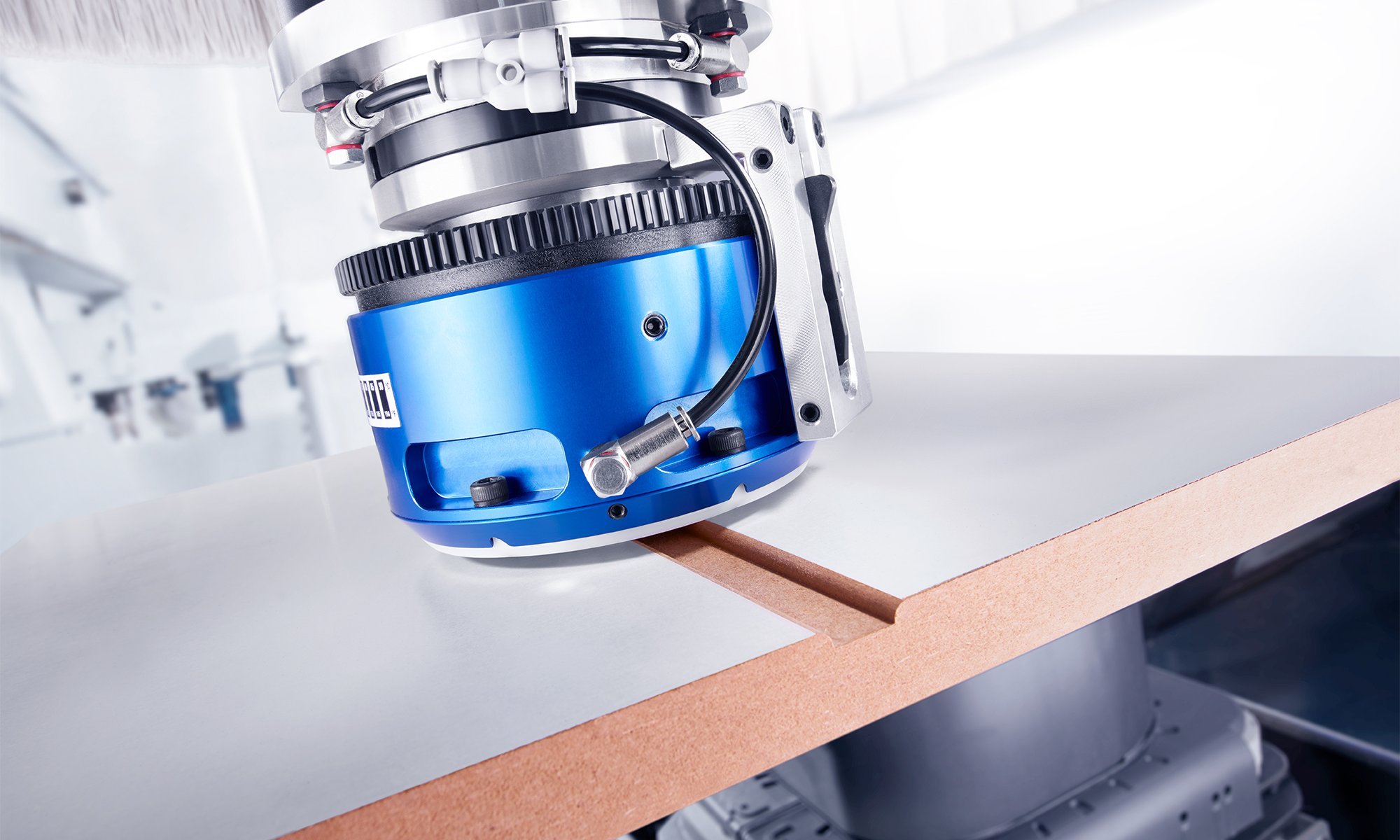

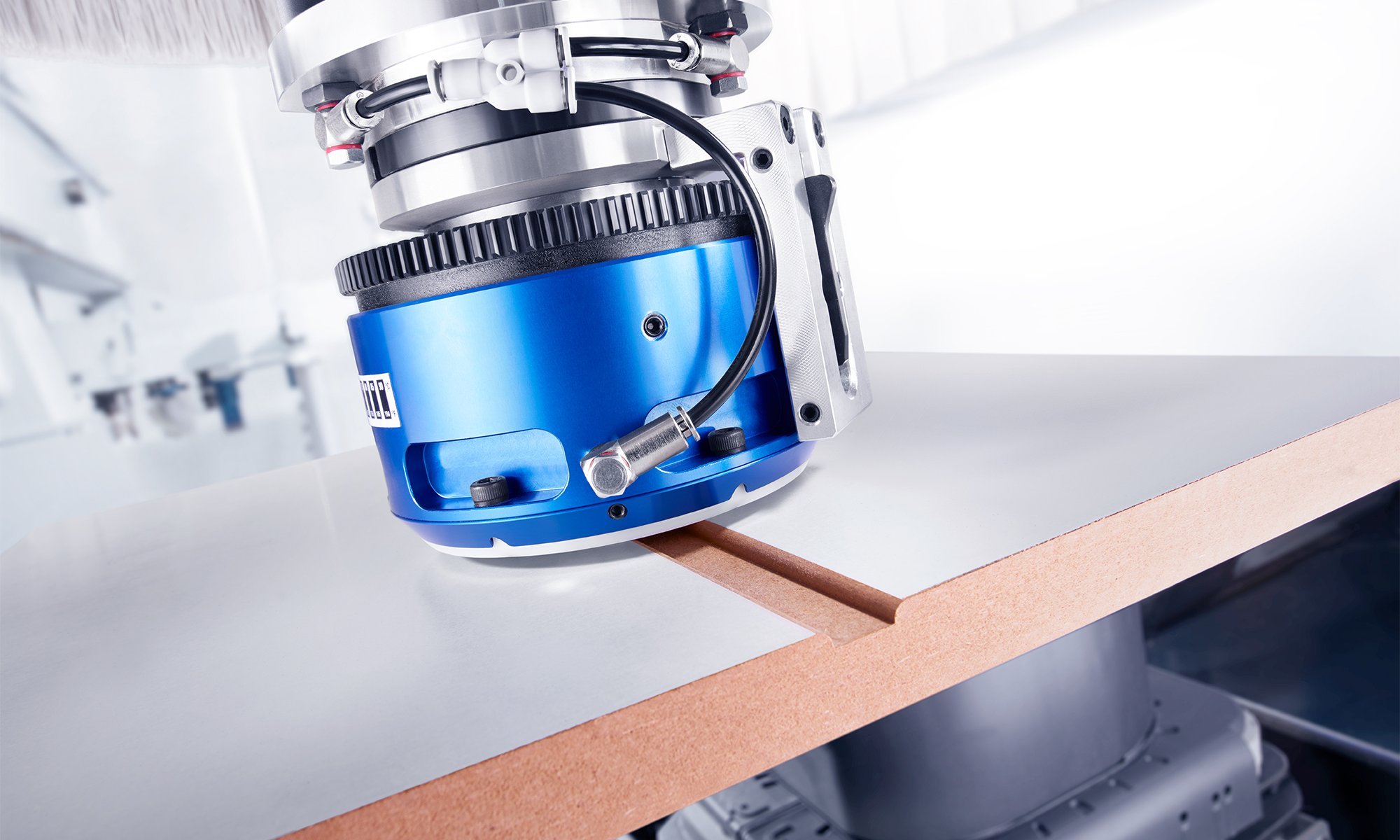

Together with CNC unit specialist BENZ Tooling, the compact FLOATING VC unit was found to be a machining solution where other products had previously failed.

Georg Ackermann GmbH stands for outstanding expertise and the implementation of unusual solutions. Anyone who has visited the Cité Musicale in Paris, the ECB in Frankfurt, or the Louvre in Abu Dhabi is familiar with the perfectly designed projects of the Wiesenbronn-based company.

More than 120 employees produce solutions for carpenters, woodworkers, shopfitters, and trade fair constructors in a 12,000 m² facility using state-of-the-art manufacturing techniques. One major topic that comes up time and again is traced machining, in which the reference surface to be machined is mechanically copied and milled, drilled, or sanded at a defined, consistent distance from the workpiece surface.

Ackermann had already tried various solutions for engraving, in which a chisel is used to mill 1 mm deep into a painted surface at 18,000 rpm and the engraving is then filled with white paint – with moderate success.

Finally, at LIGNA, Manfred Weid discovered the FLOATING VC probe unit in a compact design for vertical probing.

“At first, I had my doubts about the design, thinking that it would certainly not be as suitable as a powerful, heavy-duty unit. After all, powerful and heavy-duty are automatically associated with stability. And this unit is simply much smaller.”

Manfred Weid, General Manager at Ackermann

But this turned out to be one of the unit's many benefits and was a real eye-opener for users. Today, Manfred Weid knows that big and heavy doesn't necessarily mean stable and suitable. Because of their size and the large bearings that go with it, massive units aren't suitable for high-speed machining.

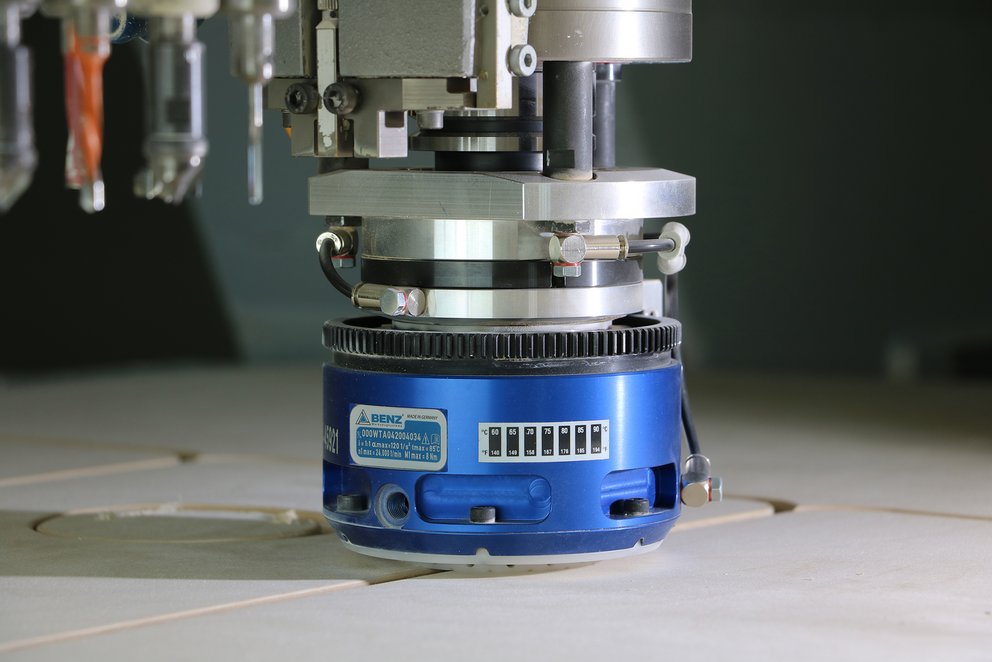

Ackermann then used the BENZ floating unit to complete the engraving work over several weeks in three shifts. “We have not noticed any wear and tear to date, and the temperature development is very low at 35°C during operation,” says the general manager enthusiastically.

This is made possible by the maximum applicable speed of 24,000 rpm and the built-in fan wheel, which provides additional cooling at high speeds. An encapsulated machining area and the fan wheel serve to improve the removal of chips into the machine extraction system. In addition, the optional blow nozzles remove the chips from the machining area.

No chips accumulate between the tracing ring and the workpiece, which could otherwise lead to inaccuracies in machining, and the machine room itself remains largely clean. The small-area tracing bell with an inner tracing ring diameter of 50 mm also contributes to more accurate machining results, as the reference surface is scanned closer to the tool.

The FLOATING VC unit also impresses in terms of smooth running: even at high speeds, noise levels are low.

But it's not just the performance of this little compact wonder that has impressed users at Ackermann. Another factor is the simple tool change: “The tool change is logically designed and easy to perform. The tool is secured using just one easily accessible clamping screw on the side,” says Manfred Weid, summarizing the advantages for the user.

In addition, the tool can be adjusted to the workpiece surface with an accuracy of 0.01 mm using a particularly easy-to-use fine adjustment mechanism.

We are happy to assist you!

Because an educated decision based on your requirements will help maximize the efficiency, precision and profitability of your CNC machining operations.