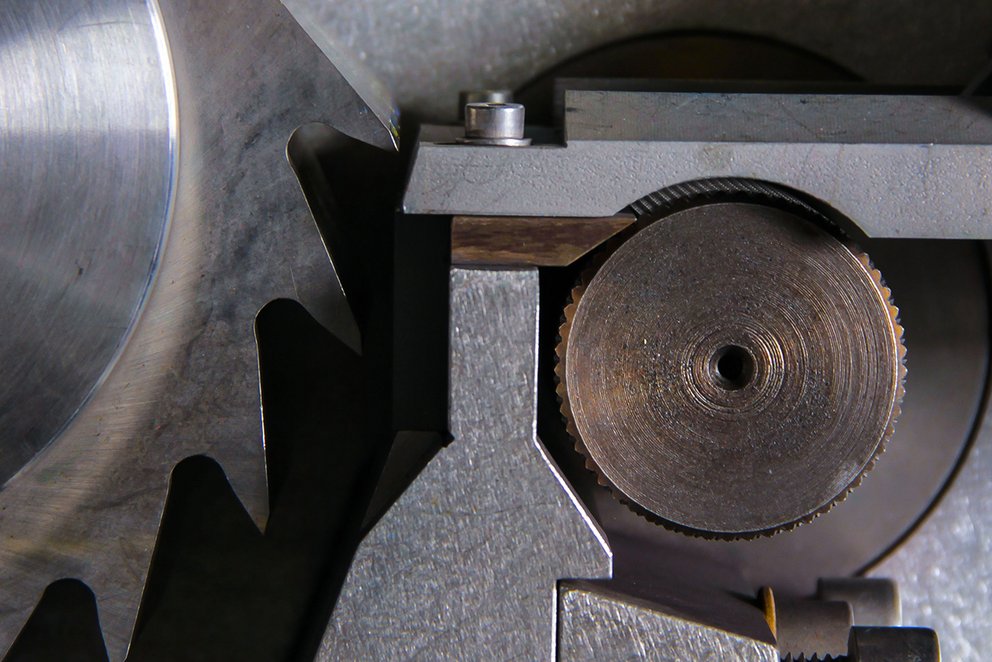

A machine is made up of various machine elements such as gear wheels, roller bearings or crankshafts. These metal parts are not only manufactured and machined with the highest precision by BENZ aggregates. They are also installed in other machines, which in turn manufacture other parts.

Ergo: BENZ technology is often integrated all over machines.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Challenge us – we are sure to find the right solution together with you.