All versions of BENZ JET use the same HPC- spindle technology, which is provided by Colibri spindles. The High Pressure Coolant model uses the machine's own high pressure coolant supply to drive the tool.

The spindle is therefore ideal for machines with a high coolant pressure. With an optimized machining result and increased efficiency of your processes, you can reduce machining time by up to 70%.

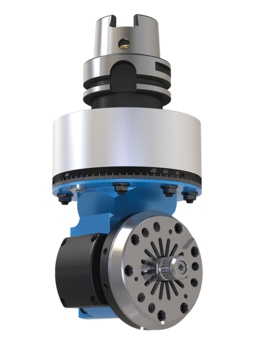

The high-speed spindle is quickly prepared for operation using a standard tool holder with a collet chuck. Cutting tools are clamped with an ER11 spring collet.

BENZ High-speed spindles are used when the spindle speed of a machine and the resulting cutting speed is not sufficient for machining, which is often the case with older machine types.

Reduce your production time and protect your machines through

Without torque support

With torque support

We give advice: from the initial idea to planning and installation. Because our goal is to support you in your tasks.

Challenge us – we are sure to find the right solution together with you.