Wind turbines have to meet extraordinary requirements in terms of statics and durability of the individual components. Despite their robust construction, the manufacturing of wind turbines is real precision work. Many classic metalworking operations such as milling, drilling and tapping come into play here.

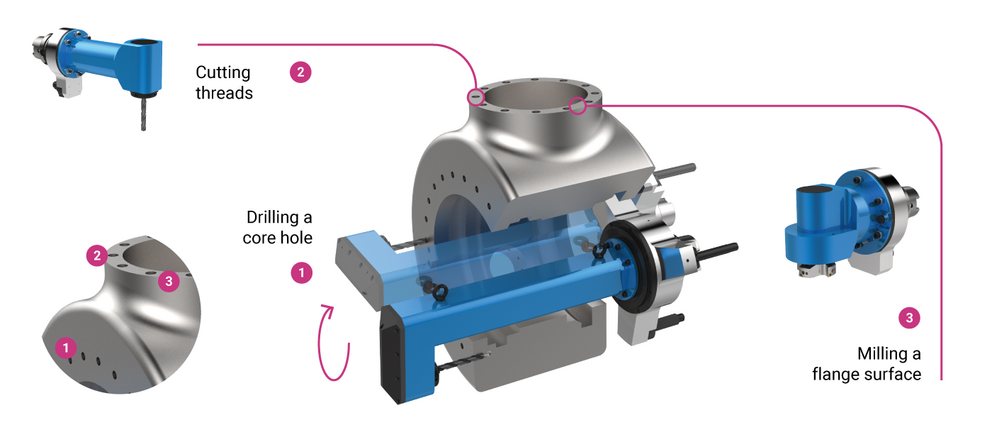

Thanks to a multi-sided tool holder BENZ exchangable units guarantee high time savings and a low error rate in your individual production processes.

An entire industry is now involved in generating electricity from the power of the wind. Even in ancient times, people used the energy of the wind via windmills to power their machines. By the end of 2021, wind turbines with a total rated capacity of 838 gigawatts had been built worldwide – a fourfold increase in the last decade – and the trend is rising. Source: GWEC Global Wind Energy Council

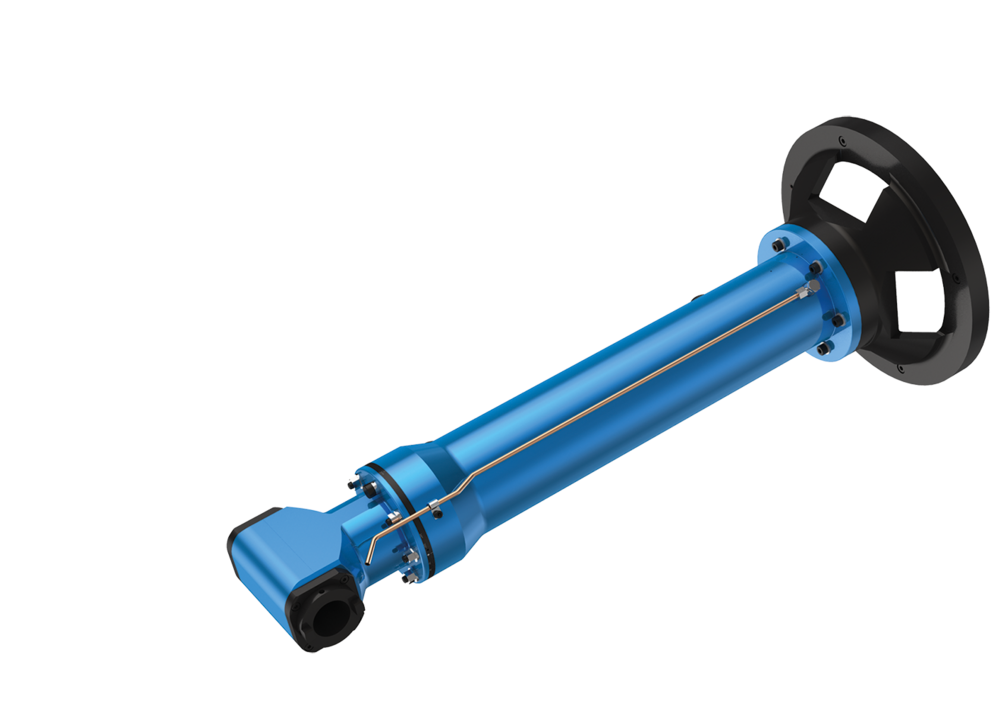

With BENZ aggregates tailored to the needs of the wind energy industry, we make a decisive contribution to developing sophisticated solutions together with and for wind power companies.

Our example shows the possible applications of BENZ exchangeable units for rotor hub processing.

The possibility to perform different production processes with only one aggregate creates a high time and thus cost advantage. Furthermore, by eliminating the need for changing processes, your BENZ unit as well as your tools and machine parts are protected against wear. This results in a longer service life.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Challenge us – we are sure to find the right solution together with you.