In addition to higher cutting speeds and precision requirements, reducing equipment and machine downtimes is a central theme in production that involves machining. A substantial factor for success is the integration of a modular tool interface.

On the video tutorial you can see step-by-step the tool change on the turret with BENZ Capto™.

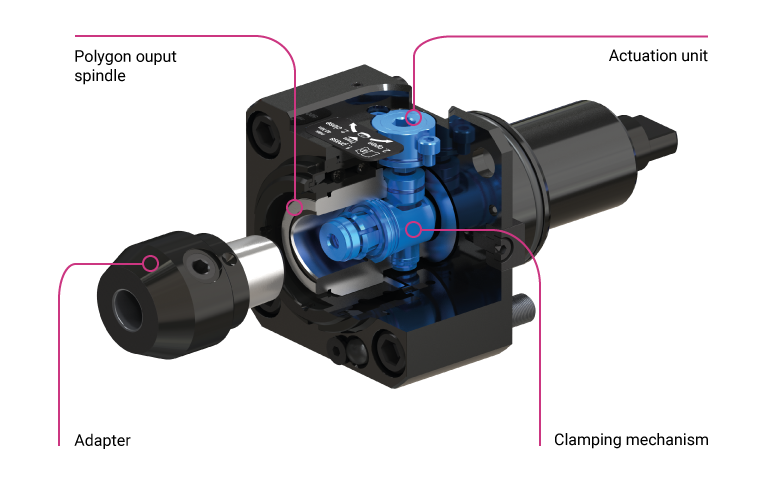

The modular quick change system BENZ CAPTO™ guarantees an extremely compact desgin by being integrated into the spindle. Special clamping kinetics for clamping forces are noticeably above the required range of ISO/DIS 26623-2.

BENZ CAPTO™ can be used for milling, drilling and turning, with up to 100 bar coolant pressure. The system is especially suited for heavy duty milling and machining.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Contact us! We are happy to give advice and find the best solution together.