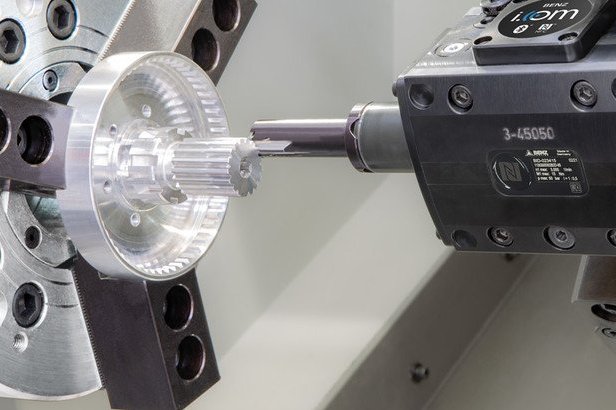

Broaching units from BENZ make it possible to machine materials that have high tensile strength. An eccentric is used to convert rotary motion from the drive shaft into linear motion on the drive side.

The plunger dips into the workpiece with the cutter and removes material after the shaping process using the integrated lift-off device. At the same time, the lift-off device avoids wear and prevents the cutter from breaking during the return motion coming out of the workpiece.

The shaping and lift-off function is carried out by the shaper and not by the machine. All of the kinematics of the shaping process are integrated into the powered shaper. No heavy machine components are moved for removing material.

Thanks to our many years of expertise and the broaching units of the BENZ LinTec series, we contribute to making your production even more efficient saving resources.

Cause our goal is to support you in your tasks – challenge us!