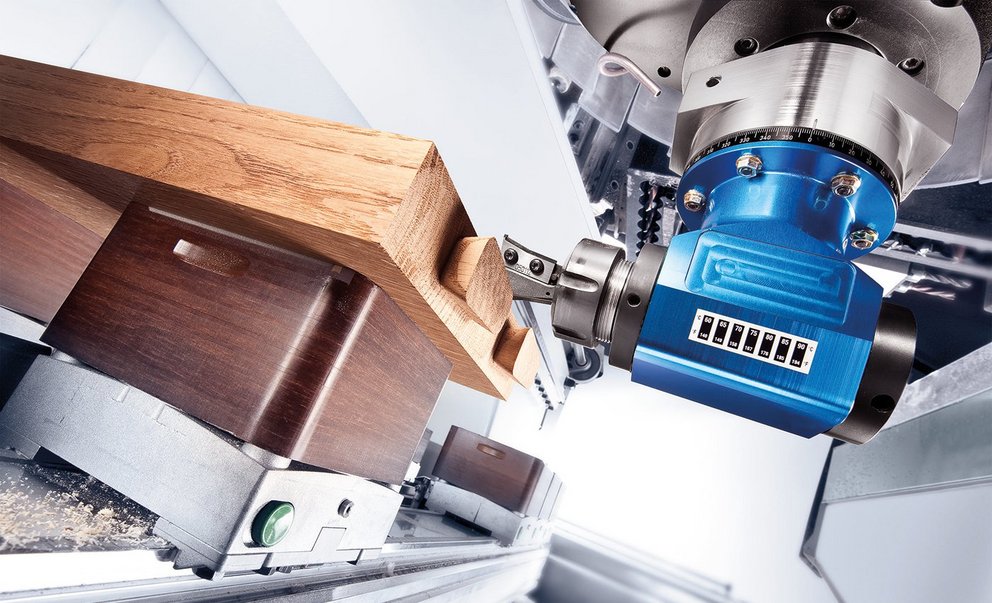

CNC units are essential components of modern wood processing machines.

They enable precise and efficient processing and thus contribute to the high quality of the final products

There are various CNC units that differ in their design, performance and function depending on the type of machining required. We explain the most important categories in the following gallery:

Choosing the right CNC unit is crucial to the success of your CNC machining project. To find the optimal CNC unit for your project, there are several things to consider; from the requirements of your project to the technical specifications of your machine. We explain the most important factors below.

We are happy to assist you!

Because an educated decision based on your requirements will help maximize the efficiency, precision and profitability of your CNC machining operations.

CNC units for wood processing are used in countless applications – with particularly precise and efficient results.

Efficiency and productivity are decisive factors in modern woodworking. In addition to ever-increasing cutting speeds and accuracy requirements, the reduction of set-up and machine downtimes is key to machining production.

This is exactly where modular quick-change systems such as BENZ Solidfix® come in.

The core principle and key advantage of modular tool changing systems is that the tool adapters can be preset outside the machine during the machining process and are ready for use. The tool change itself can be realized in less than 20 seconds.

Contact us for a quote, meet us at a trade show, or browse our product categories. We are also happy to advise you personally.