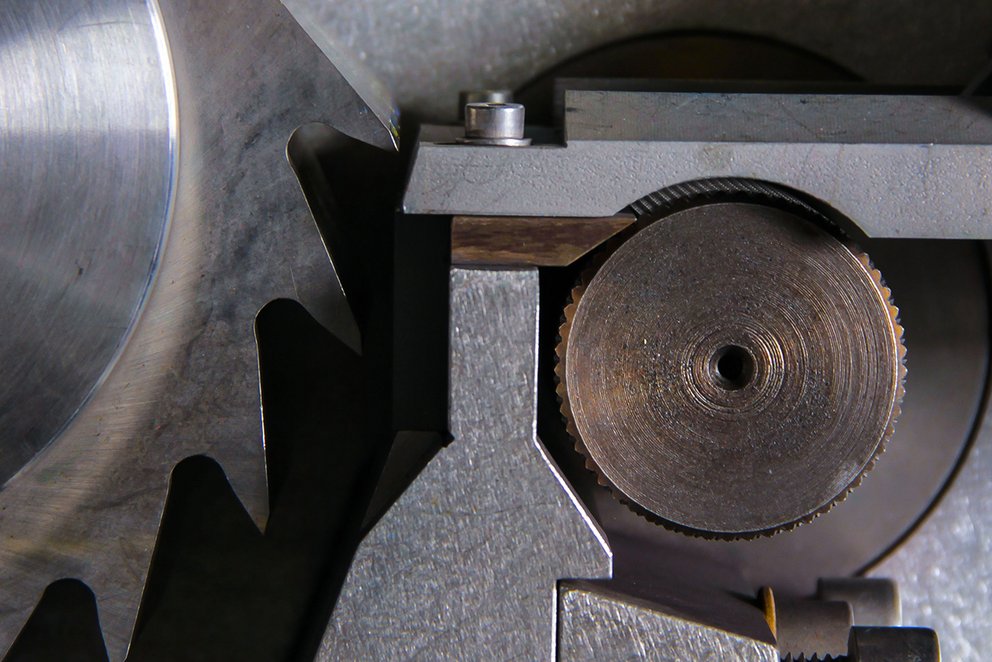

Modern CNC metalworking is simply inconceivable without suitable tools (also referred to as CNC units). These stand-alone, mechanical systems are used on CNC machines for the precise machining of metal workpieces of different sizes and complexity.

Their mode of operation is based on the precise positioning and movement of the tool in the work area – coordinated by the machine's CNC control system.

Tools for CNC machining are used in many metalworking industries that place particular emphasis on precision and efficiency.

HSC = High Speed Cutting

HSC machining enables workpieces to be machined at high cutting speeds and feed rates. This results in shorter machining times and higher productivity thanks to:

Read more about coolant driven and mechanical high-speed spindles from BENZ Tooling.

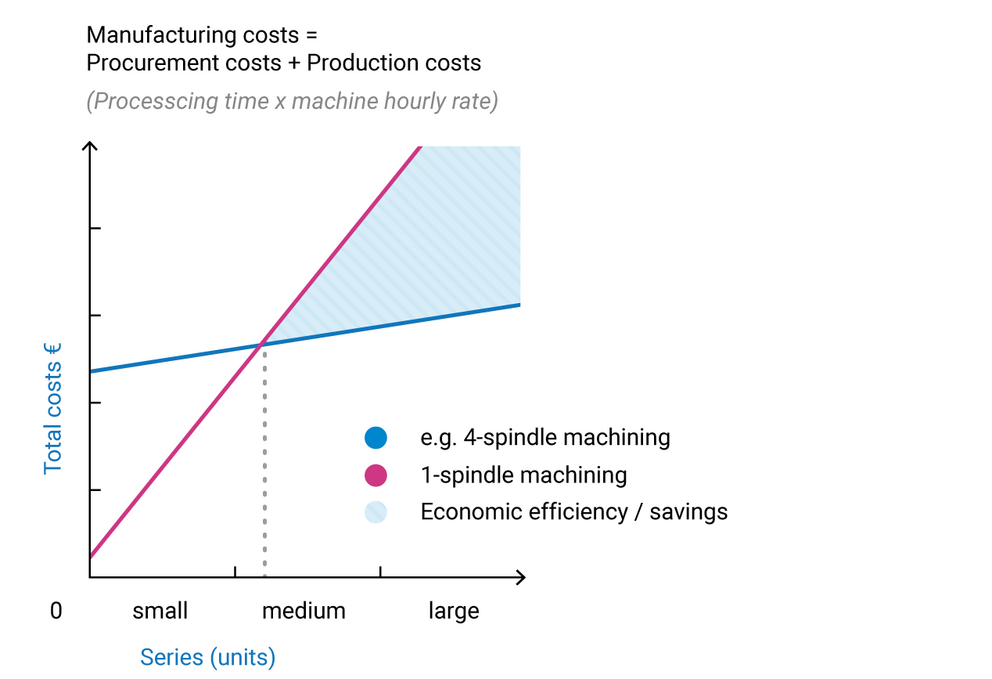

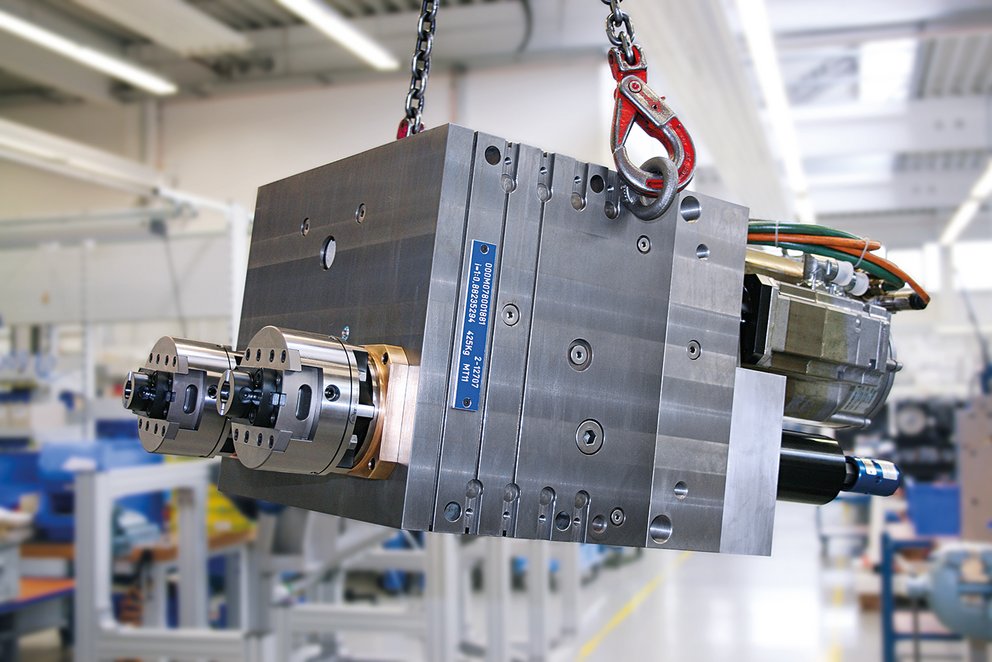

In order to reduce production costs, CNC tools with multiple spindles are typically used for medium to large series.

These so-called multi-spindle heads carry out different or similar machining operations simultaneously, hence at the same time, thus reducing the machining time per workpiece.

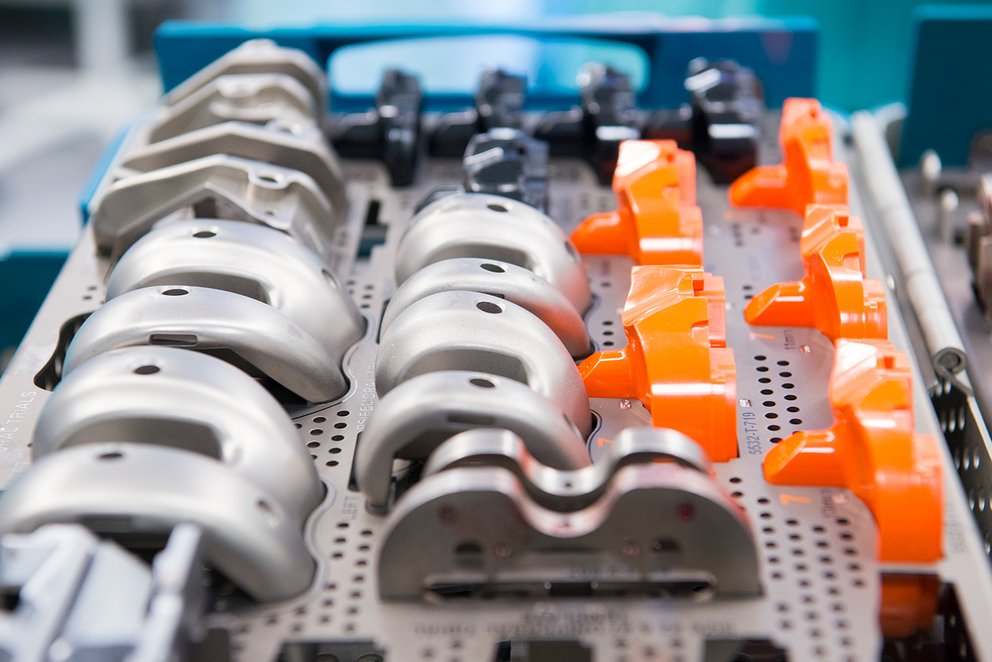

The potential applications are virtually limitless: drilling, tapping, counterboring, reaming, milling, etc. The variety of products is equally diverse:

from lightweights to 5t heavyweights

We give advice – from the initial idea, through planning and installation, to machine acceptance.

Thanks to our versatile product world, you have the option of gearing your machinery exclusively to metal processing or combining it with tooling systems for wood and composite materials.

Tool changing systems reduce machine set-up times significantly, as the tools can be changed without recalibration and often even directly during the machining process.

Changing the CNC units is done manually or automatically, depending on the conditions of the machine.

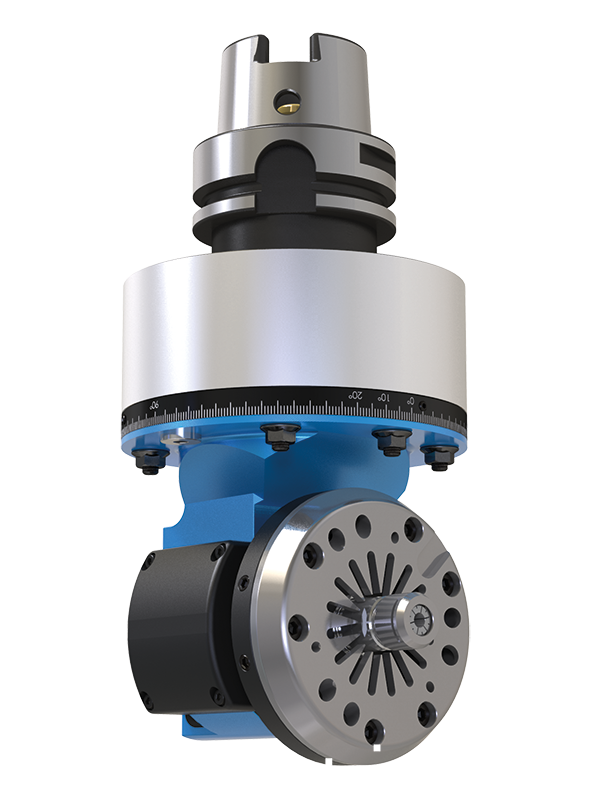

The basic principle and key advantage of modular tool systems such as BENZ SOLIDFIX® and BENZ CAPTO™ is that the tool adapters can be preset outside the machine parallel to the machining process. Thus they are directly available and ready for use.

Tool magazines contain a large number of tools that can be changed automatically. The CNC machine control manages the tools in the magazine and selects the right tool for the respective machining operation.

Hybrid versions combine the advantages of different systems. BENZ Hybrix, for example, is a rotating tool carrier system with a fixed base housing. The main component of the magazine is one or more stationary motorized spindles.

Tools can either be removed from the carrier system (magazine function) or remain in the carrier system (turret function). In combination with the automatic tool change, this is particularly cost-, space- and time-saving.

Contact us for a quote, meet us at a trade show, or browse our product categories. We are also happy to advise you personally.