For the machining of components in the automotive industry, BENZ Tooling offers technical solutions at the highest level! You benefit from the ambition of our engineering team, because technical innovation is ingrained into our very identity.

We keep in close contact with our customers to ensure that we know today what our customers will need tomorrow. Our product range includes both standard and clever detailed solutions which are designed specifically for individual customer needs.

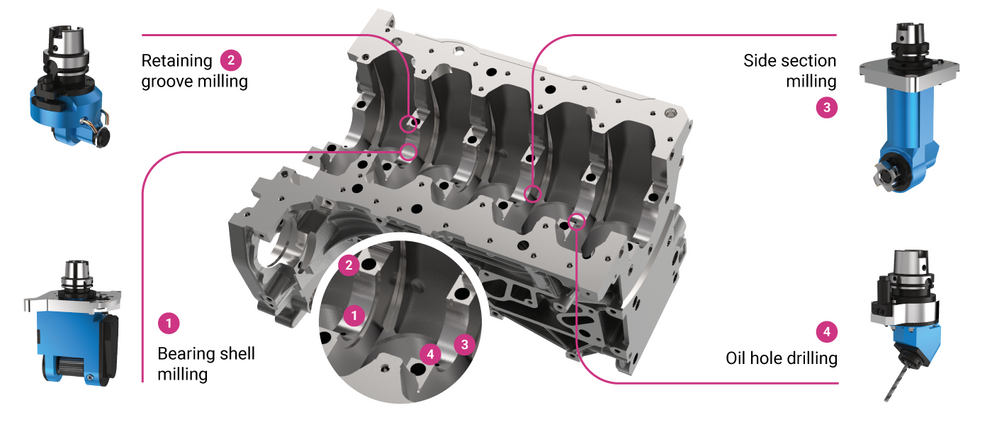

Use of BENZ aggregates in the engine block machining of an automotive manufacturer