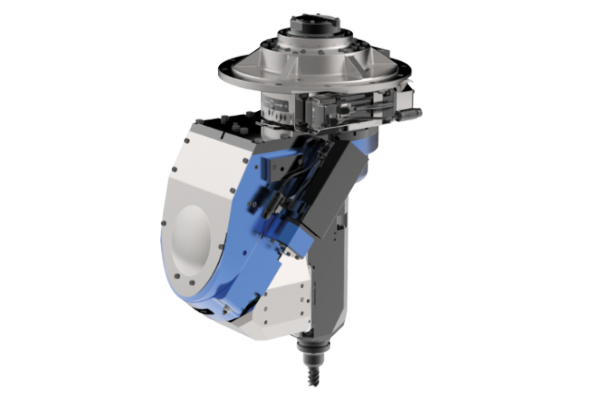

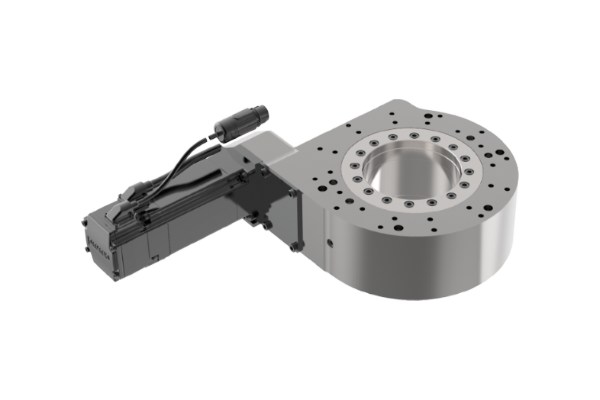

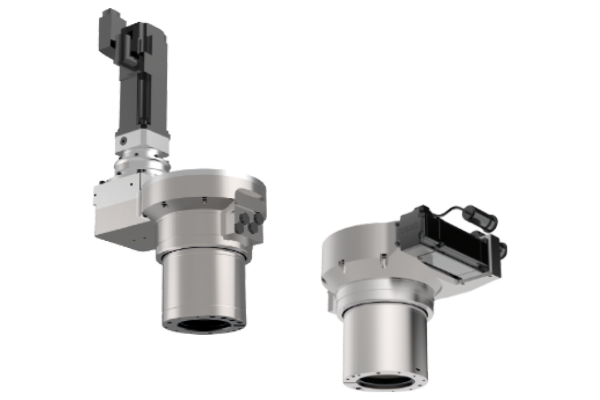

The perfect addition

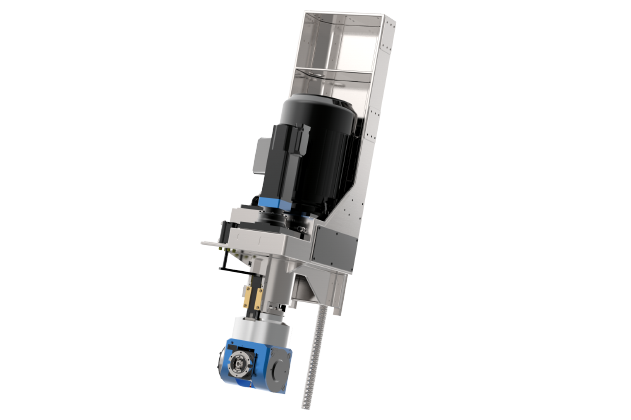

Do you wish to do horizontal processing around a workpiece without changing the tool, but you don't have a machine with a C-axis? Or maybe individual machine elements must be provided with compressed air, electricity, or another medium?

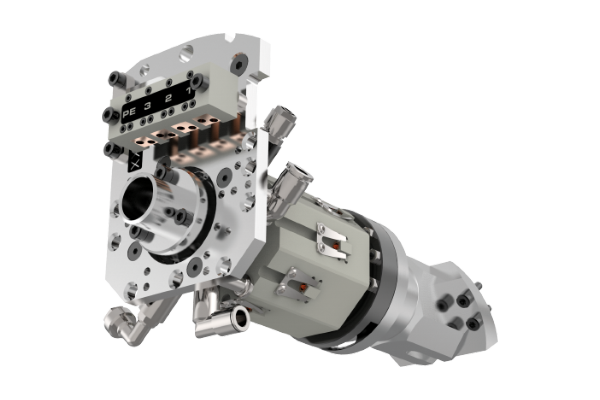

BENZ Tooling has a variety of system components that work flawlessly with your existing solution.