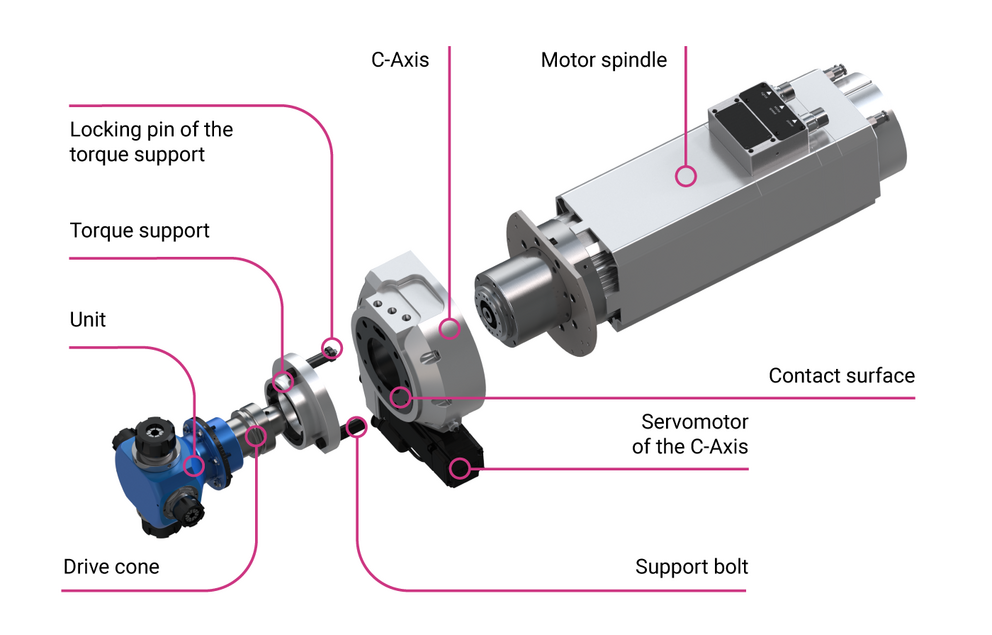

The motor spindle is the heart of every machining center and crucial for the performance of the machine and the quality of the processed workpieces.

Spindles ensure maximum precision and productivity in machine tools.

Compact and powerful motor packages with high-precision bearings are a requirement for high speeds and excellent concentricity values.

We give advice – from the initial idea, through planning and installation, to machine acceptance.

Thanks to our versatile product world, you have the option of gearing your machinery exclusively to metal processing or combining it with tooling systems for wood and composite materials.