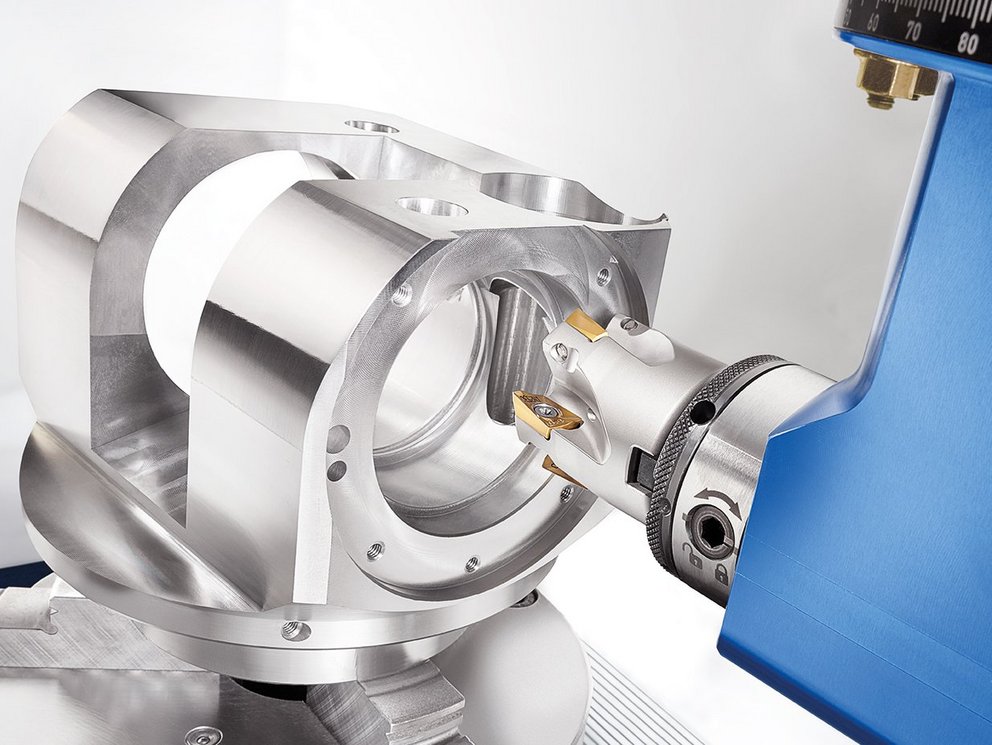

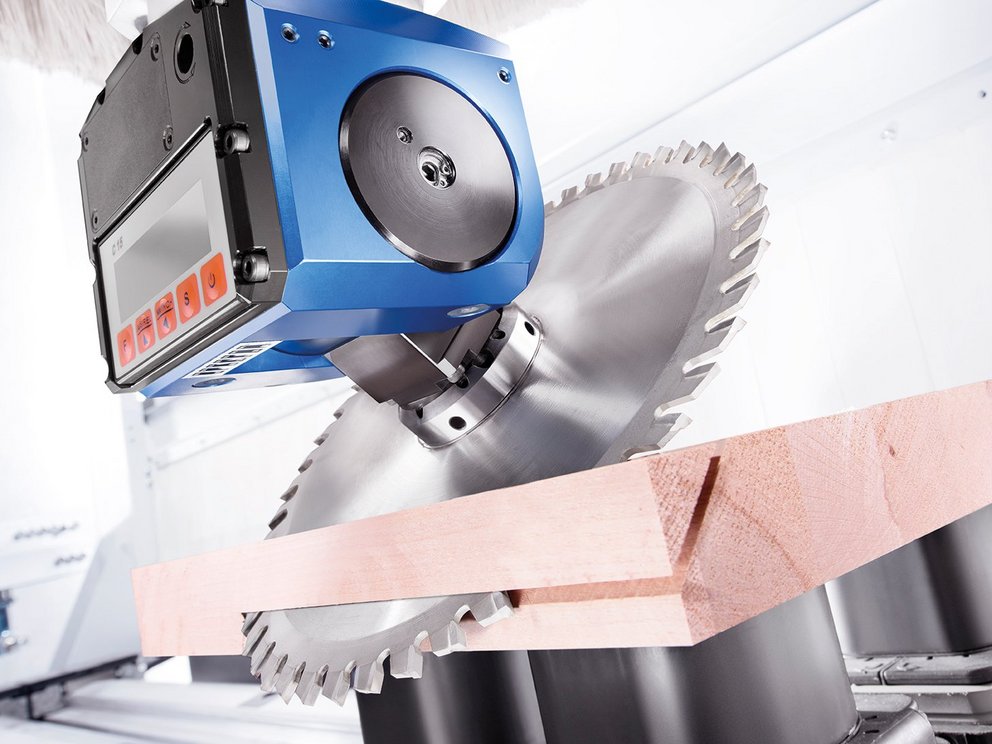

Tools are used in many areas: from metalworking and woodworking to composites processing.

In contrast to machines, which generally automate a specific process, tools are specially designed for a specific task or operation. The variety of products ranges from simple cutting tools to complex machine tools.

Tooling technology is a crucial component of industrial processes and will continue to play a vital role in the success of modern industry in the future. From high-tech electronics to high-precision machine components and Industry 4.0 products – the know-how of tool technology can be found everywhere. Modern tools built with this know-how create competitive advantages like

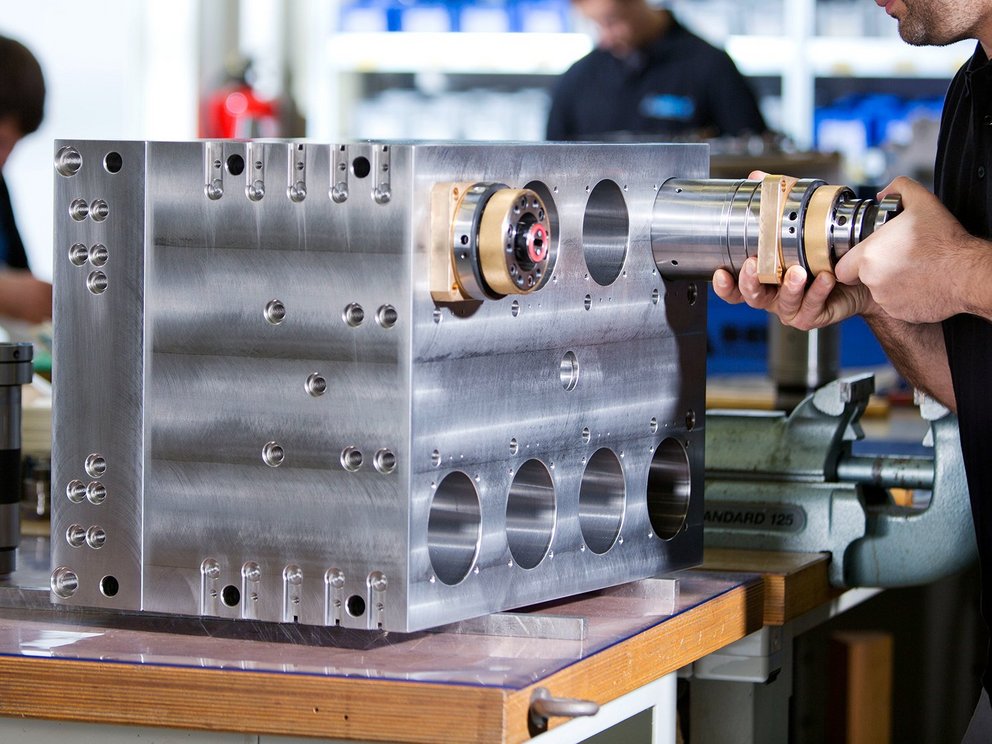

Discover how our team's many years of expertise in tool technology produce innovative solutions and make a decisive contribution to the success of demanding industrial projects. Our in-depth knowledge and industry expertise make us a global partner for new challenges for machining and turning centers in metal, composite and wood processing.

Whether standard components, modular construction kits or customized solutions: BENZ Tooling offers a wide range of products that are used in all important sectors of metal, wood or composite material processing (e.g. automotive, electromobility, aerospace, wind power, medical technology, lightweight construction).

On our website you will always find new reports from customers who have mastered challenges together with BENZ Tooling. Check back regularly to stay up to date and discover more inspiring stories about tooling technology in practice.

We are happy to assist you!

Because an educated decision based on your requirements will help maximize the efficiency, precision and profitability of your CNC machining operations.

Tool technology is facing the challenge of continuously adapting to the changing requirements of industry and developing solutions that meet the increasing demands for efficiency, precision and flexibility.

An important trend in this context is the increasing integration of digital technologies and data analysis methods in machine tools and manufacturing processes. The networking of machines and tools through Industry 4.0 enables manufacturing processes to be optimized, efficiency to be increased and valuable data to be used for decision-making.

We have recognized that Industry 4.0 and digital transformation can only succeed as a union. Cooperation is becoming increasingly important, especially in the field of digitalization, as communication between different systems plays a crucial role. Accordingly, we have developed a digital strategy for Industry 4.0 together with EWS from Uhingen, Germany. With such innovation projects, we are laying the foundations for future product developments, e.g. in the sensor technology of tool systems.

The future of tooling technology is characterized by innovation, change and overcoming global challenges. Companies that rise to these challenges and develop innovative solutions will be the winners. We support you with our expertise and innovative strength. We offer you tooling solutions that are geared towards the needs of Industry 4.0, sustainability and resource conservation.

In our download area you will find a large number of tool technology catalogs and brochures.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Challenge us – we are sure to find the right solution together with you.