A quick tool change system for automotive suppliers like the Schaeffler Group

The company, which is globally renowned for the production of couplings and gears for the automotive industry, is headquartered in Bühl at the foot of the Black Forest. LuK operates a tool shop with a workforce of around 260 at its sites in Bühl and Kappelrodeck. Here, mainly clamping and forming tools as well as device parts, i.e. manufaturing equipment, are produced mainly in single-item production.

In order to adequately meet increasing requirements as a result of greater capacity, three new CTX beta 500 Gildemeister turning centers were purchased. Equipped with a 12-compartment servo revolver for powered tools, the machines also enable drilling and milling operations, eliminating the need to reclamp workpieces in other machines for these work processes.

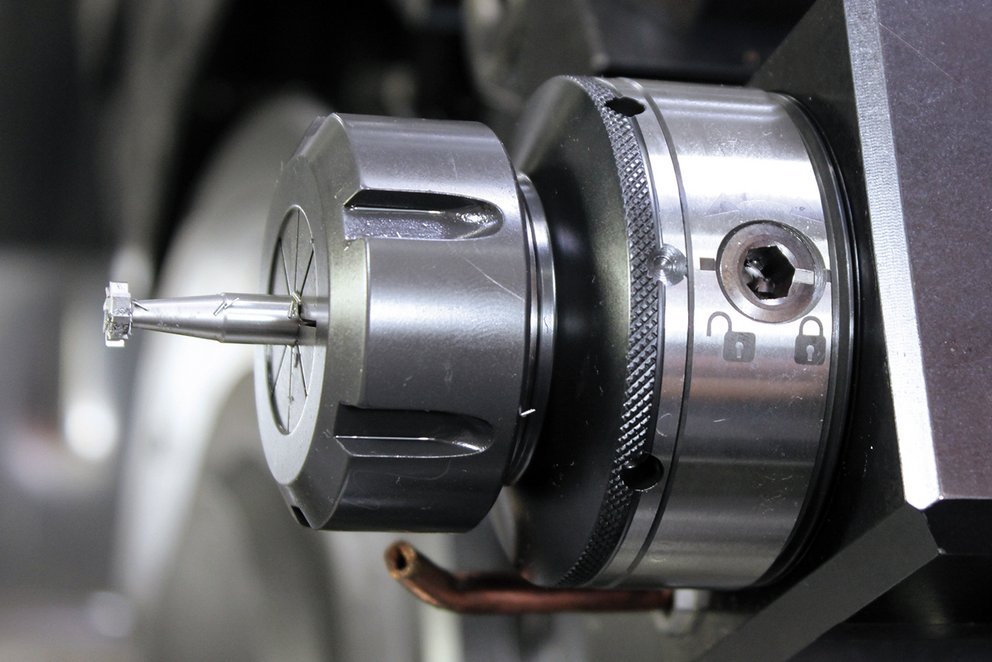

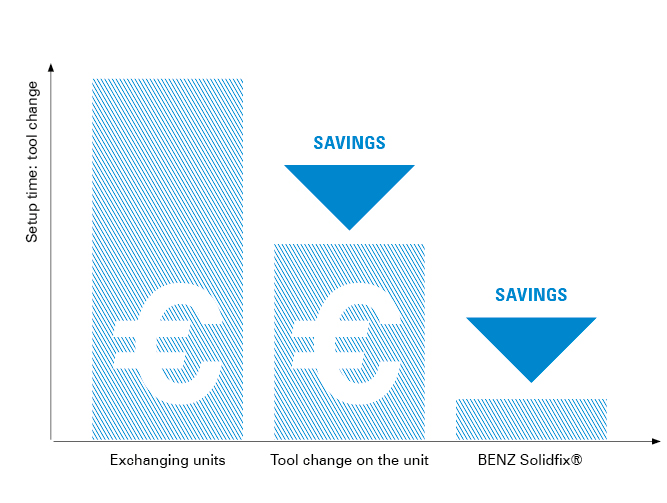

In order to also save set-up times during the relatively frequent tool exchange, LuK has equipped the new machines with a tool quick-change system. Different systems on the market were analyzed at length by the technology department, with the goal of finding the best possible solution.