System partnerships between manufacturing companies and tool manufacturers are more important today than ever before.

The introduction of BENZ Solidfix® at automotive supplier Grieshaber demonstrates the advantages that both sides can derive from such partnerships.

Grieshaber is a manufacturer of precision parts that produces over 120 million parts annually, primarily supplying the automotive industry. As a member of the Grieshaber Group, the core competence of the Schiltach-based company in the Black Forest lies in the processing of non-ferrous metals and stainless steel. The supplier succinctly describes its philosophy with the motto “Success through high quality and strong partnership.”

Under these premises, Grieshaber has been pursuing a close technology partnership with the tool specialist BENZ Tooling from Gengenbach for several years. This combination of development and application expertise has now yielded a number of advantages for both sides. A culture of “learning from each other” has long since developed, regularly leading to sophisticated innovations. With their technical and consulting expertise, the Gengenbach-based company not only solves problems within the framework of established technologies, but also introduces new approaches and technologies for Grieshaber.

One of these innovations was the deployment of the BENZ Solidfix® modular quick-change system. “During our first visits to Grieshaber's production facility, we noticed that each lathe was equipped with a relatively large number of non-modular units. This meant that a lot of storage space was required directly next to the machines,” recalls the BENZ Tooling sales manager. However, this was only the initial reason for presenting the quick-change system to the partner, as it offers far more advantages than just minimizing storage space next to the machine and saving on tool costs.

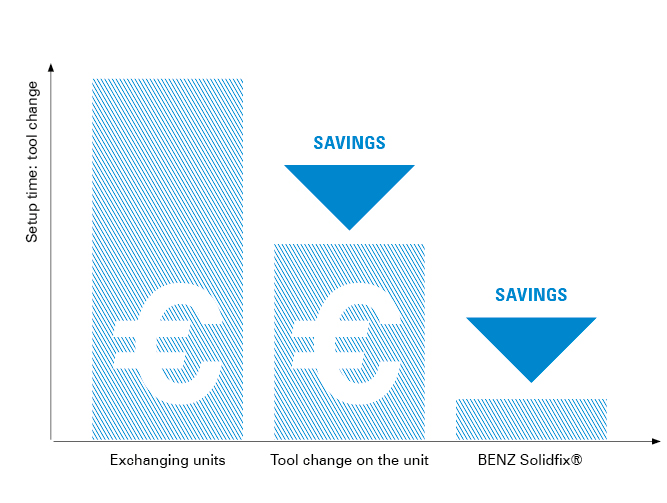

Machining companies are regularly confronted with demands for higher cutting speeds and accuracies as well as shorter setup times. On lathes, these demands can be met with a modular tool interface, among other things. With such interfaces, the conventional replacement of the entire tool unit with long downtimes is a thing of the past. Instead, only the tool adapter is replaced.

The tools can be measured and adjusted in parallel with the machining process. The preset adapters can then be exchanged on the base unit within a few seconds. This enables a reduction in machine downtime of up to 90 percent.

The video shows a complete tool change with BENZ Solidfix® in less than 20 seconds – see for yourself.

“Since its introduction 15 years ago, our modular system interface has achieved a very high level of acceptance in the industry and exceeded our ambitious expectations. We have also succeeded in attracting well-known system partners who have worked with us to successfully establish the Solidfix interface on the market.”

Michael Kempf, Director Sales BENZ Tooling

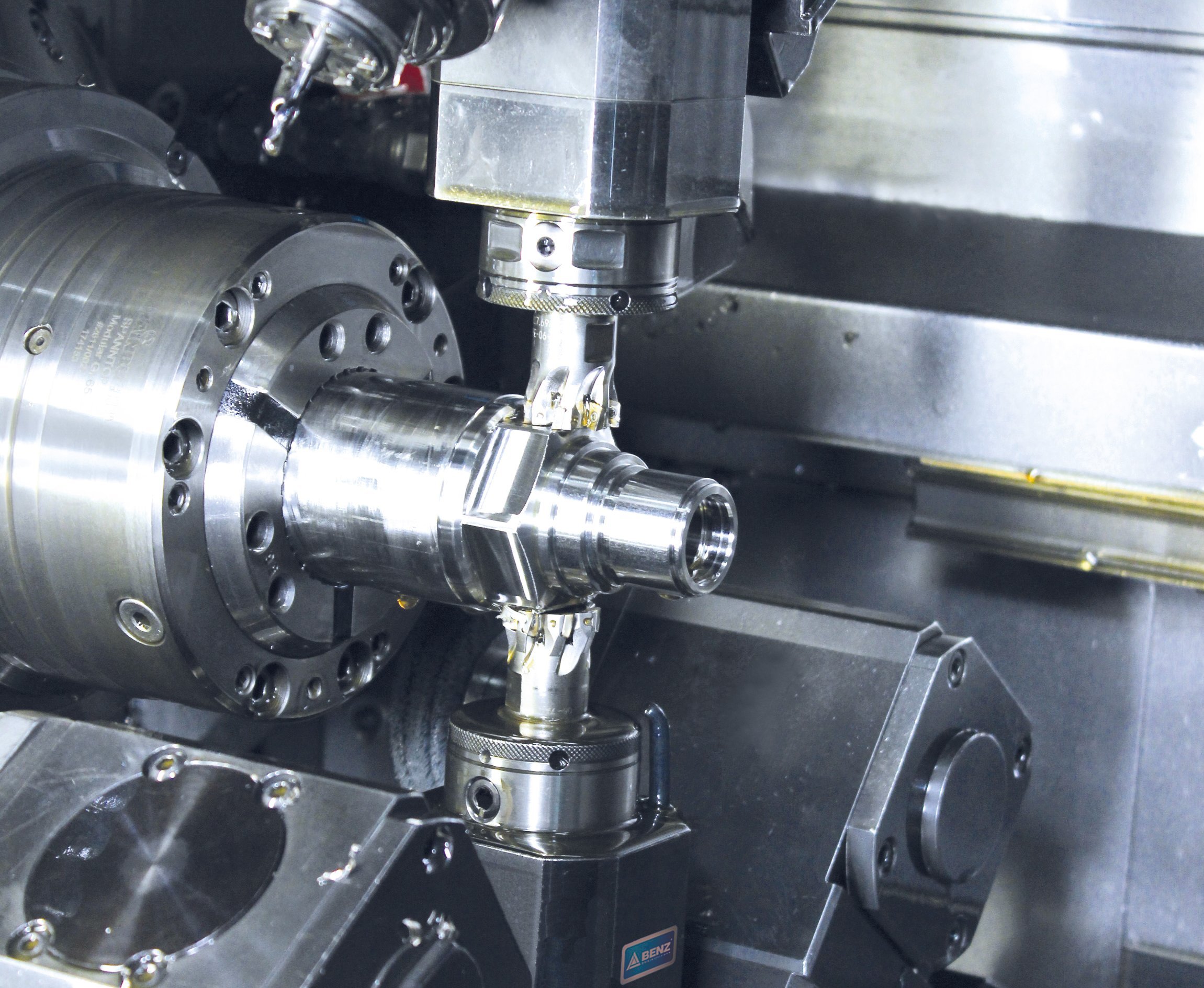

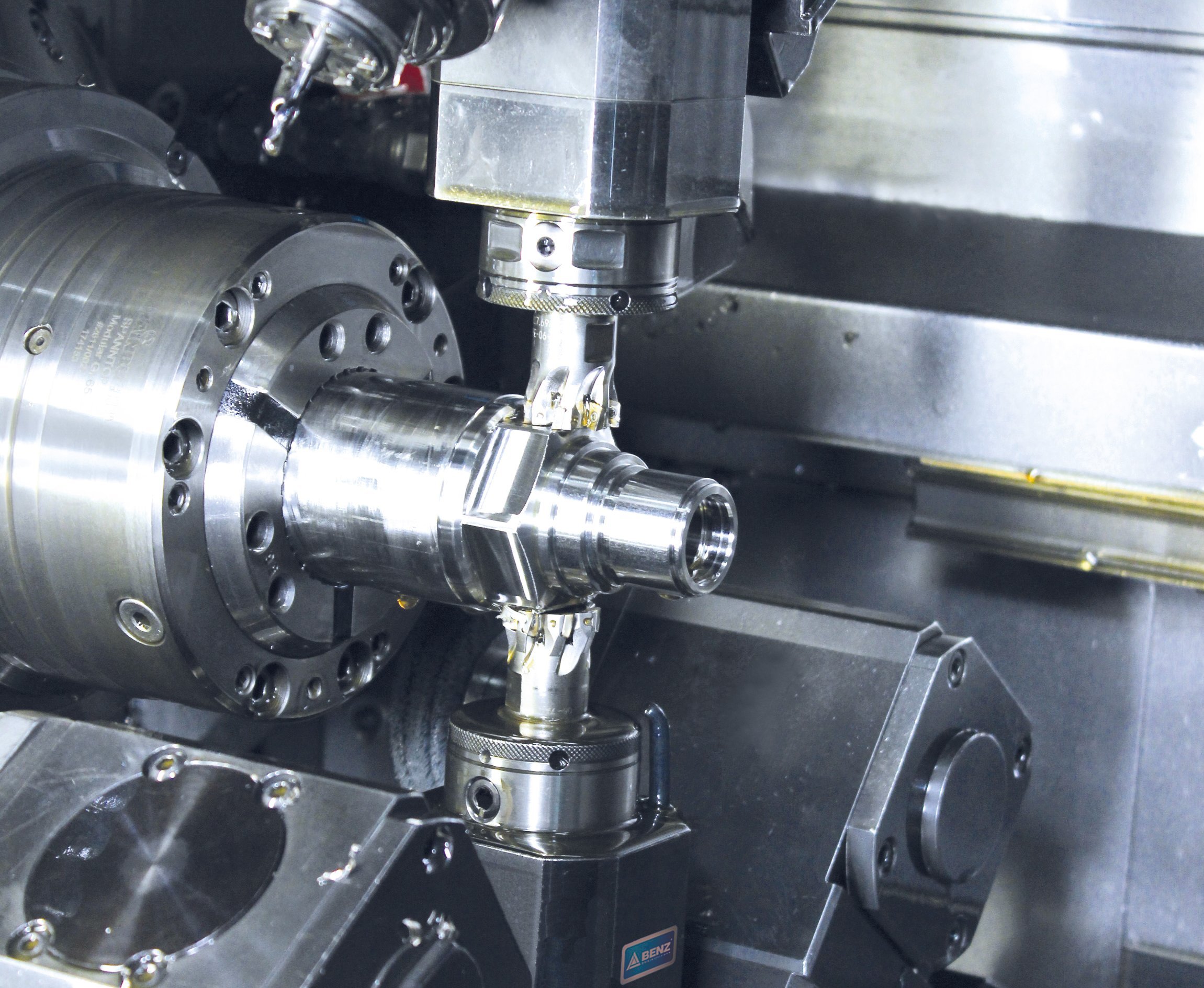

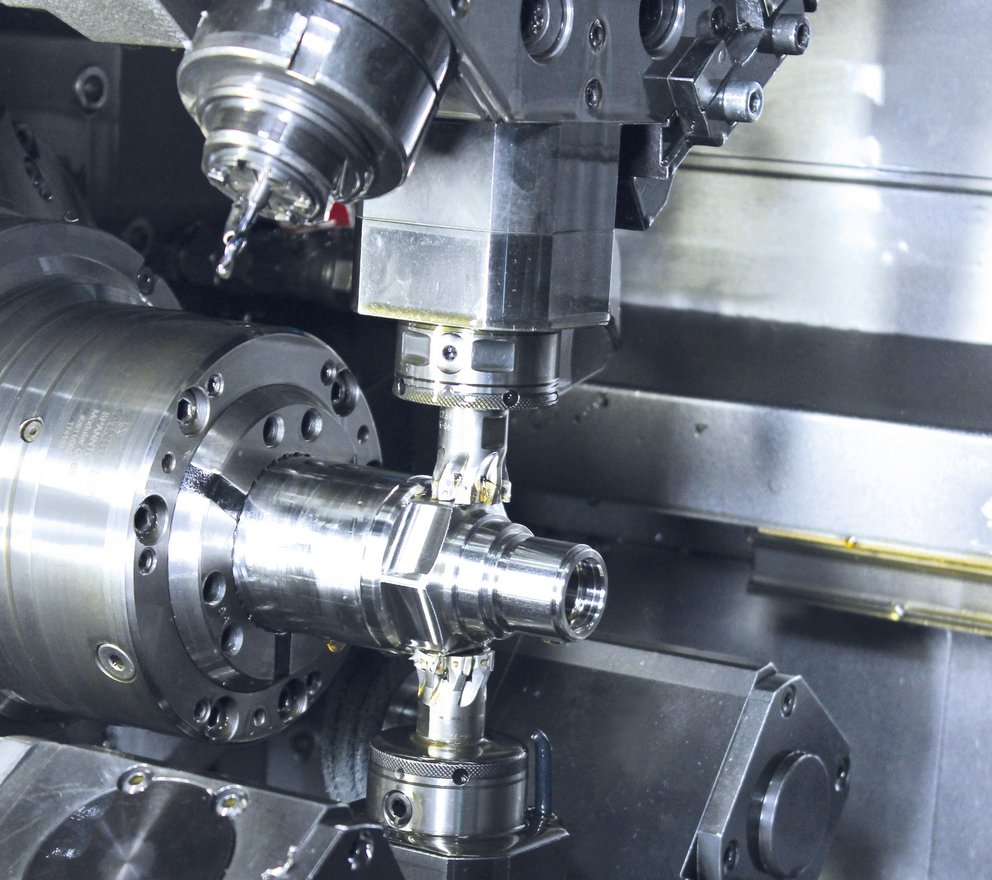

Thanks to the combination of play-free cone centering, large contact surface, and high feed forces, the system offers a high degree of stability and resistance to tipping, ensuring that even the requirements of milling operations are reliably met. This means that BENZ Solidfix® can be used for drilling, milling, and even sawing operations, requiring fewer driven tools than in non-modular operation. At the same time, significantly less storage space is required because only the adapter is changed when changing tools and the driven tool remains on the machine.

“For the reasons mentioned above, we expected that the use of BENZ Solidfix® would significantly reduce investment costs compared to conventional machine equipment,” says Günter Weißer, Production Manager at Grieshaber. In other words, there were enough optimization opportunities to start a new project in Schiltach: the implementation of BENZ Solidfix® as a modular standard system in Grieshaber’s production.

The goal of the project was to use the modular system for machining stainless steels and, among other things, to mill key surfaces up to a width of 115 mm and a height of 20 mm. This application requires a particularly large number of tool changes in a relatively short time.

In order to be able to use the quick-change system, certain adjustments had to be made to the system. “First and foremost, the mounting of the unit had to be optimized to cope with the high loads generated by heavy-duty machining. In addition, the BENZ Solidfix® adapter range was expanded to include basic holders for screw-on milling cutters, so that Grieshaber can continue to work with its preferred cutting tool manufacturer,” reports Michael Zink.

Michael Zink, project manager at BENZ Tooling, supervised the partnership with Grieshaber centrally on site from the outset and concludes: “With a high level of application expertise, Grieshaber played a constructive role in shaping the project.”

Frieder Heizmann, Head of Stainless Steel Machining at Grieshaber, echoes this sentiment: “The collaboration was excellent at all times, both in terms of interpersonal relations and results.” Mark Vollmer from Grieshaber's CIP team, who supervised the long-term tests, was also very satisfied with the interface.

Today, BENZ Solidfix® is used on Index machines of the C100, C200, G200, G250, and ABC types for milling, drilling, and threading complex parts, including heavy-duty machining. The focus is on machining duplex steel 1.4462 and 1.4404, as well as other stainless steels. One task here is to mill a wrench size of 46 with a diameter of 52 mm in a single pass. In 1.4404, two surfaces are milled simultaneously. The tool used for this – a WP milling cutter with five cutting edges – has a diameter of 20 mm.

“BENZ Solidfix® has completely impressed us in this and other applications. There are no quality deviations compared to the non-modular tools used previously. Today, the first component after changing the adapter is even more accurate than after changing the entire tool holder. There is no need for time-consuming on-machine spindling.”

Günter Weißer, Production Manager at Grieshaber

In addition, the BENZ interface guarantees the same tool life and offers simple, well-thought-out handling.

“In the future, we want to equip new machines with BENZ Solidfix® or other modular tool systems from BENZ Tooling right from the start,” concludes Frieder Heizmann.

BENZ Tooling is also looking to the future: "Our technology partnership has already given rise to another project on which we are working closely together. This involves setup-optimized tool systems for multi-spindle automatic lathes. We are also delighted about the cooperation in technology transfer." This refers to a visit by Grieshaber trainees to BENZ Tooling. This collaboration is also to be continued by both sides and will serve the further development of both companies.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Contact us! We are happy to give advice and find the best solution together.