Our goal is to optimize your manufacturing process. BENZ multi-spindle heads support you in the economical machining of your workpieces by minimizing the main and non-productive times and thus reducing your production costs.

Typically, multi-spindle heads are used for medium to large series.

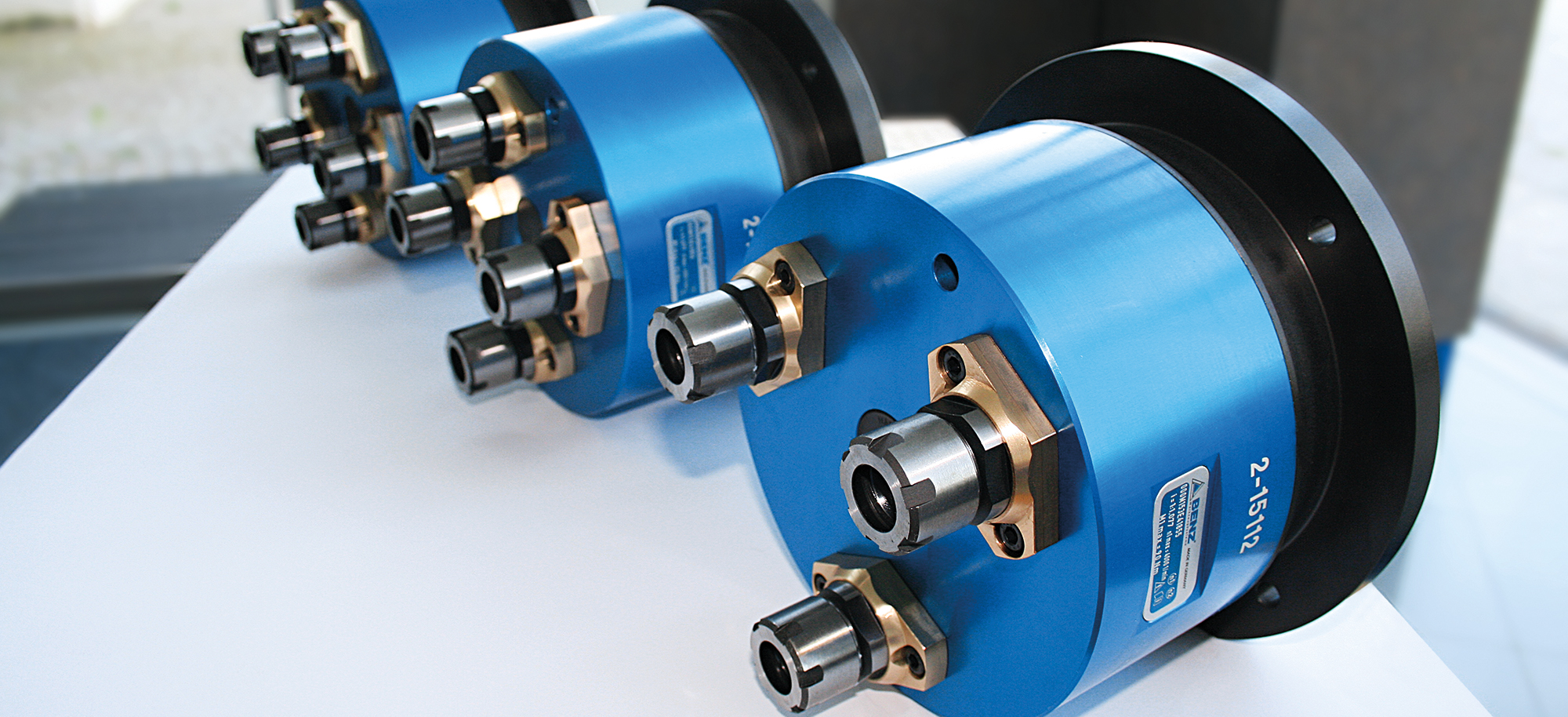

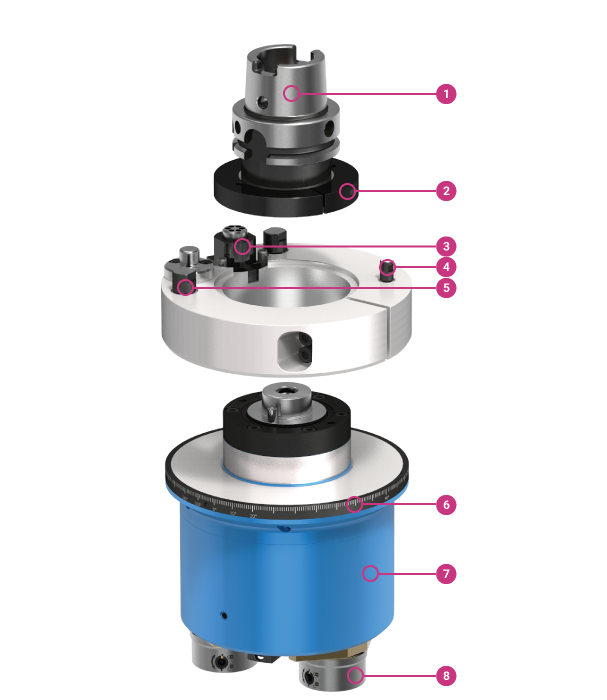

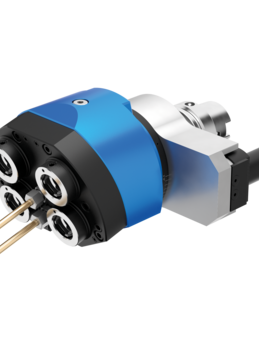

The potential applications are virtually limitless: drilling, tapping, counterboring, reaming, milling, etc. The variety of products is equally diverse. Using proven standard components as a basis, we work in close coordination with you to find the perfect solution for your application:

All BENZ multi-spindle heads have one thing in common: they impress with the highest performance, precision in machining and quality that keeps you one step ahead.

We maintain close contacts with leading mechanical engineering companies and therefore have the vital know-how to develop the extraordinary.

Challenge us – we are sure to find the right solution together with you.