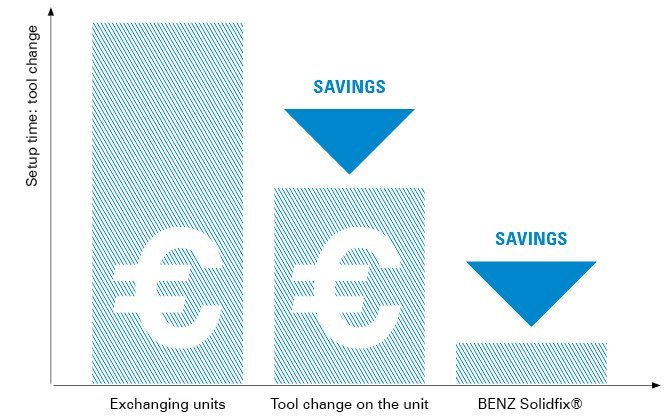

In addition to higher cutting speeds and precision requirements, reducing equipment and machine downtimes is a central theme in production that involves machining. A substantial factor for success is the integration of a modular tool interface.

The basic principle and the key advantage of modular tool system comes from the fact that the tool adapters can be preset and made ready for use outside the machine while the machining process is in progress.

Due to the modular design, only the adapters are exchanged – the basic unit remains on the machine. The adapters can be exchanged very quickly. Thus you increase the value-adding operating times of your machine.

At the same time, you save costs, because the acquisition of additional units can also be reduced to a minimum.

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Contact us! We are happy to give advice and find the best solution together.

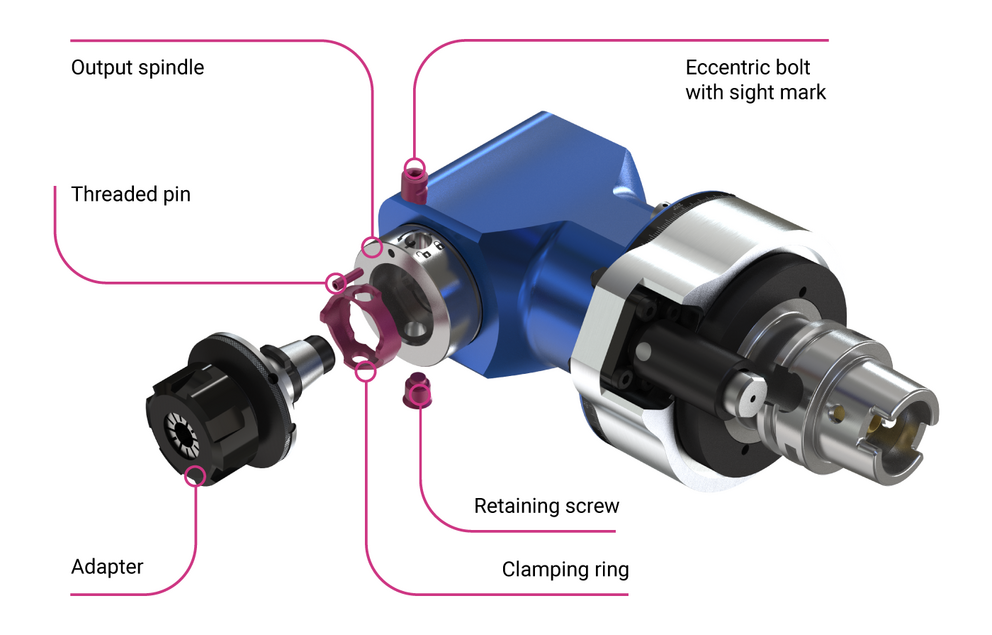

The combination of tailstock centering that is free of play with an extremely large planar support, in conjunction with high clamping forces, enables BENZ Solidfix® to offer maximum tilt resistance and stability, which fulfills the requirements of milling.

The high torque transfer and the high potential speeds also characterize the performance capability. This is supported by a special clamping mechanism, which operates centrally, without lateral forces, and works together with the high-precision and compact components to achieve top values for concentricity, flexural strength and repeatability.