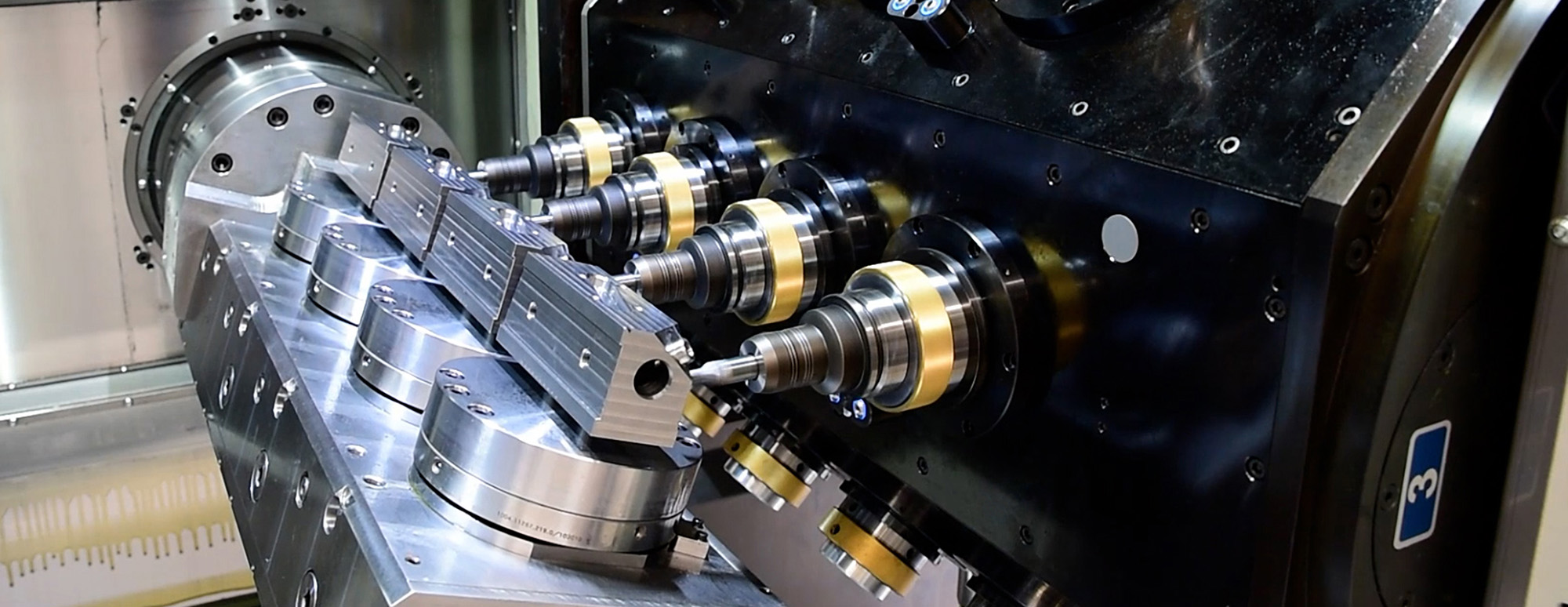

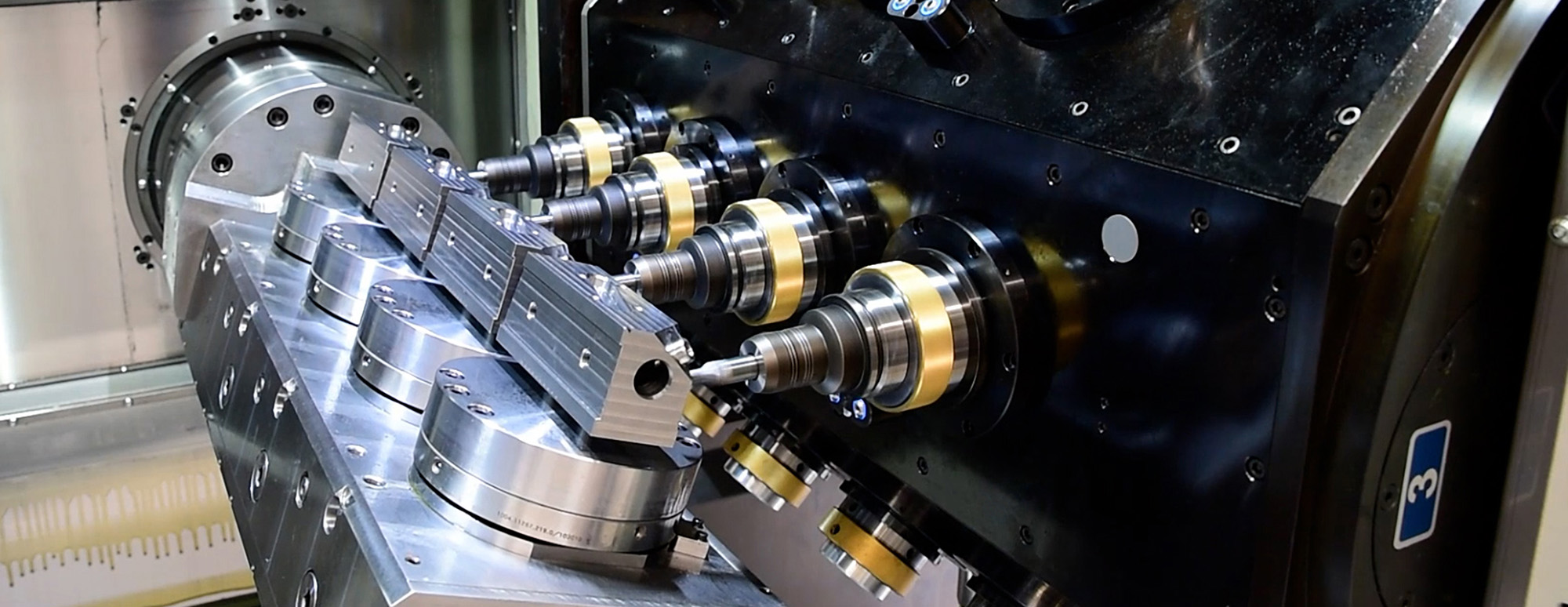

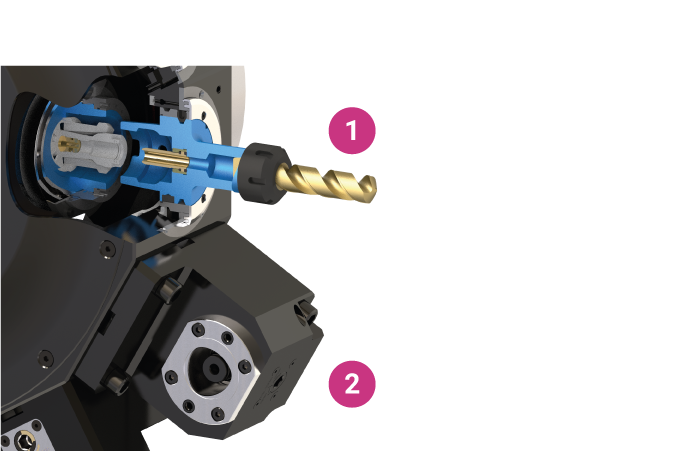

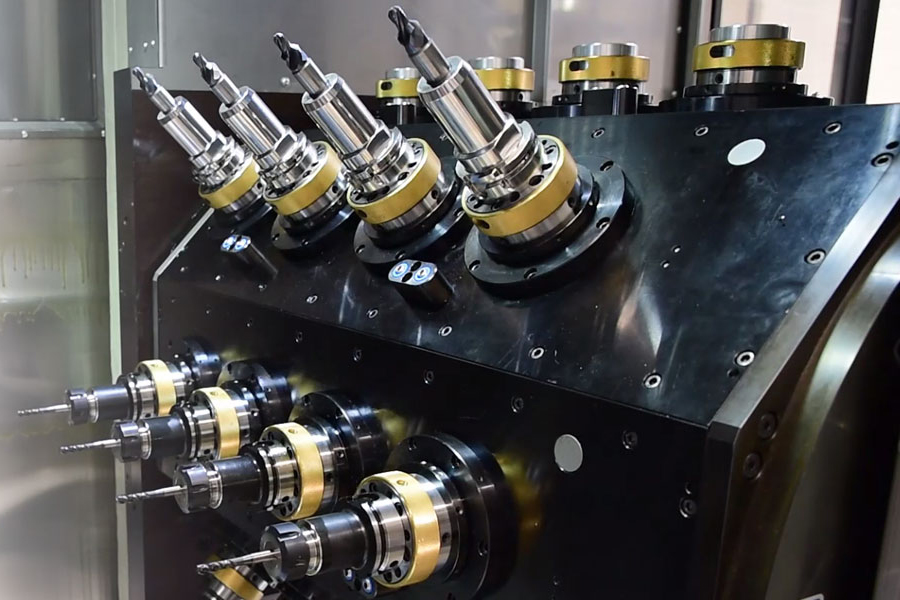

BENZ HYBRIX is a rotating tool carrier system (magazine) with a fixed housing. The main components of the magazine are one or more stationary motor spindles with an automatic tool exchange system.

The technology is suitable for all machine types. Versions in a star (single-row, multi-row) or crown design are possible.

Other configuration parameters

Our goal is to support you in your tasks. Thanks to many years of expertise and the right BENZ aggregates, we are here to help to make your production easier and more efficient.

Contact us! We are happy to give advice and find the best solution together.